When it comes to resistance welding, choosing the right electrode is crucial for a strong weld. High copper alloys are an excellent choice for spot and seam welding due to their electrical and thermal conductivity and wear resistance.

Resistance welding is an essential process in various industries to join two or more metals. It uses pressure and electric current to join two or more pieces of metal. The success of this process depends, among other things, on the proper selection of the resistance welding electrode.

In this blog post, we will discuss factors to consider when choosing a resistance welding electrode, how different welding processes affect the choice of welding electrode, and what high copper alloys have to offer when it comes to resistance welding electrodes.

Factors to consider when choosing a resistance welding electrode

Choosing the right resistance welding electrode ensures a strong and durable weld. Therefore, it is crucial to have an overview of the overall situation before purchasing a resistance welding electrode. First and foremost, it is essential to know what type of base metal you are welding. The type of material to be welded is critical because different materials are used for resistance welding electrodes, including copper and others. Each of these materials has unique properties, but they are not always a perfect match for the material to be welded.

Secondly, the type of application for which the welding is required is also essential. Some applications require high accuracy and precision, while others require high current capacity. Thus, different electrode materials and shapes are used for different applications. Other factors to consider when purchasing a resistance welding electrode are:

- Electrical conductivity: The electrode should have high electrical conductivity to reduce heat loss during welding.

- Thermal conductivity: The electrode should have a low thermal conductivity to prevent overheating and damage to the electrode during the welding process.

- Durability: The electrode should withstand the high temperatures and pressures of the welding process without degrading or breaking down.

High copper alloys and resistance welding

Finally, the most crucial factor to consider is the welding process. Different welding processes, such as spot welding, seam welding, and projection welding, require different electrode shapes and materials.

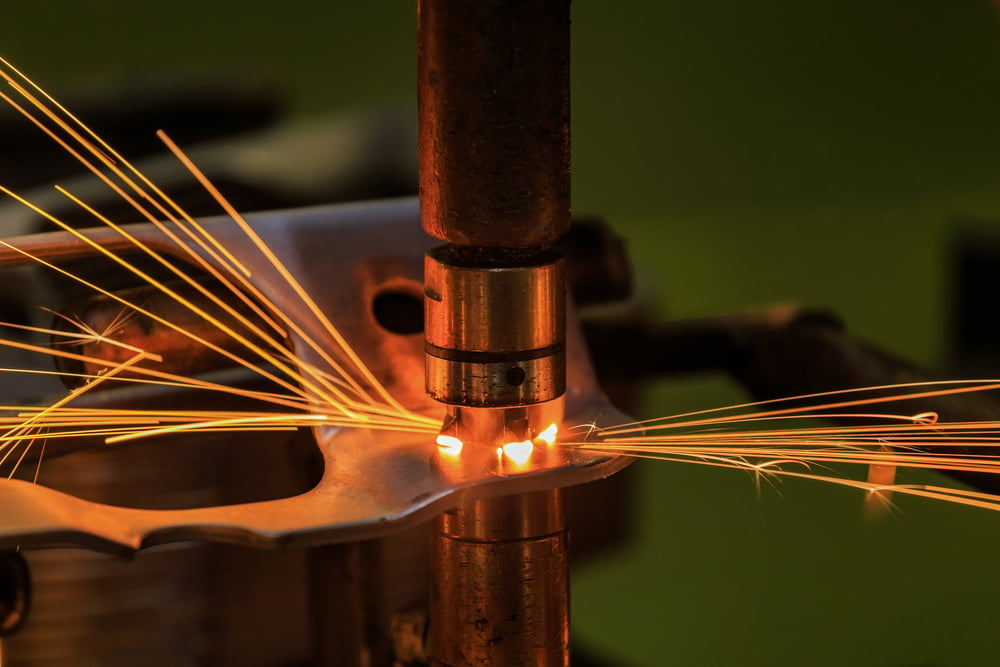

For example, spot welding requires a pointed electrode that can withstand high temperatures and pressures without deforming or melting. At the same time, it must have good electrical conductivity to ensure a strong and consistent weld. Therefore, high copper alloys are an excellent electrode material due to their excellent electrical and thermal conductivity and wear resistance.

Image: Welding tips made of AMPCOLOY®

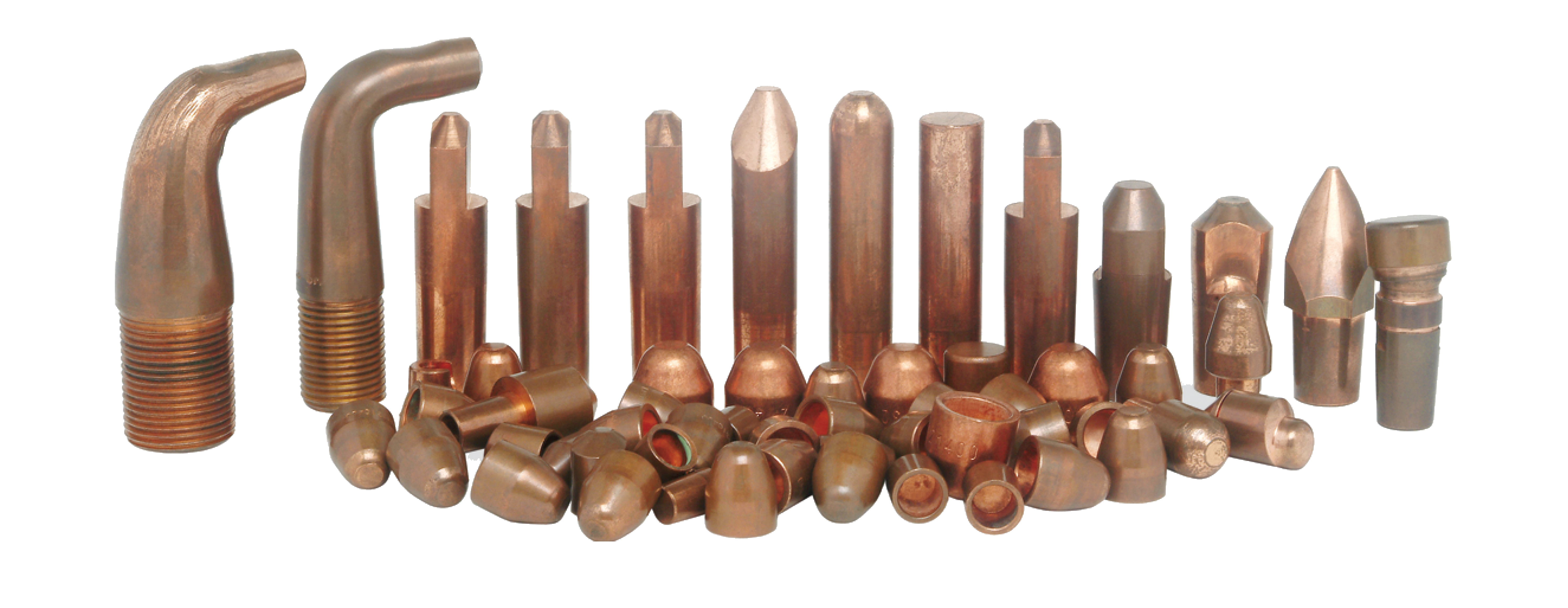

Image: Welding tips made of AMPCOLOY®

Seam welding, on the other hand, uses a wheel-shaped electrode that rotates and moves along the seam, applying heat and pressure to fuse the two sheets. The wheel electrode is often water-cooled to prevent it from overheating during the welding process. Due to its superior properties, such as excellent electrical and thermal conductivity and exceptional wear resistance, high copper alloys are often the material of choice for seam welding wheels.

AMPCOLOY® – perfect for resistance welding

AMPCO METAL has developed many high copper alloys ideal for various resistance welding components. AMPCOLOY® alloys are known for their excellent corrosion and wear resistance, high strength, and high electrical and thermal conductivity. All AMPCOLOY alloys are valued for their durability, reliability, and versatility. Unsurprisingly, welding wheels made of AMPCOLOY® 972 and AMPCOLOY® 940 are highly recommended for welding mild and carbon steel. For stainless steel welding, AMPCOLOY® 95 is recommended.

For spot welding, AMPCOLOY® 88, AMPCOLOY® 89, AMPCOLOY® 91, AMPCOLOY® 95, and AMPCOLOY® 940 are ideal electrode materials for welding high-resistance materials such as stainless steel, monel, and nichrome. Please get in touch with our experts for a specific recommendation on which material is best suited for your resistance welding needs.

For further information about resistance welding, please download our free «AMPCO METAL guide for resistance welding and anti-spatter.»