Copper alloys like aluminum bronze offer unique material properties such as thermal conductivity, corrosion-resistance, good strength and resistance to fatigue. Read in our blog post what you need to know when welding copper alloys.

Technically, welding copper alloys are not much different from welding other alloys. However, there can be some challenges, like the choice of the correct filler material, welding with similar or dissimilar metals and more. Therefore, let’s take a deeper look into what is important when welding copper alloys.

The correct filler material

Filler metals are materials that are used when welding two components together. To choose the right filler material is crucial for a high-quality end product. They exist in different forms;

- Welding wire

- Flux-cored wire

- Welding electrode

- Welding rod

A number of different factors must be taken into consideration when choosing the correct filler material, such as the compatibility with the base metal, the welding position and the welding process used. For more information about the different welding processes, check our blogposts about GMAW and GTAW respectively FCAW and SMAW.

Welding surfacing or overlaying applications

Aluminum bronze or copper are often used to surface or overlay materials. The great advantage of aluminum bronze and copper is that they both offer a good resistance to corrosion. Furthermore, they are being used to build up a bearing surface. This technique offers benefits in reducing material costs and, in salvage applications, enables an expensive or difficult-to-replace part to be reclaimed and restored to operation with minimum of downtime. It is also known as weld cladding.

Welding similar metals

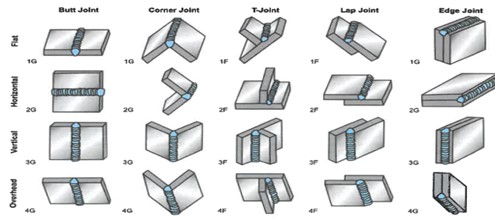

There are similarities in the welding of different copper alloys. Generally, when welding nonferrous material to itself, you do not have to preheat the base material. There are five different welding joints and four different welding positions to be distinguished as illustrated in the picture below.

When welding different copper alloys with each other, typically the butt joint is used – and, if possible, the flat position is chosen. As important as the correct filler material is the joint preparation. Here are some points you have to consider:

- The edges of the material should be beveled to achieve good penetration

- The welded joint should be at least as strong as the base metal

- The material being welded should be properly restrained to help minimize distortion when welding a long length

Welding dissimilar metals

The process of welding dissimilar metals involves the joining together of two metals that possess different properties. Because of their different chemical or mechanical properties they don’t match each other naturally. Yet, they still can be welded together under consideration of some factors. In addition to corrosion, solubility, thermal expansion and weldability, the choice of the correct filler metal is decisive.

To clarify, let’s make an example: When welding AMPCO® 18 to steel, preferably AMPCO-TRODE® 10 is used as welding filler metal, since its unique metallurgical characteristics of aluminum bronze that enables it to easily join dissimilar metals. Like AMPCO-TRODE® 10, each filler metal has it’s unique characteristic which makes it suitable for different applications.

For further information about welding copper alloys, the different welding processes and the correct filler material for your personal welding project download now our free «ultimate guide for welding dissimilar metals».