In tube forming, welding rolls and forming rolls have important tasks. In order for them to perform reliably and efficiently even under difficult and demanding conditions, AMPCO METAL has developed special copper alloys.

Roll forming is a technical process in which workpieces are formed from sheet metal. In this process, a sheet metal strip is passed through several pairs of rolls – so-called forming rolls – arranged in modular sequence until the desired profile shape is finally bent. Tubes, for example, can be produced easily and efficiently in this way.

Tubes and other roll-formed profiles produced by this exact process are in demand in a wide variety of industries. Examples include the automotive, aeronautical industry, and household products.

Three important properties for forming rolls

The most important duty of a roll forming mill is performed by the forming rolls. Piece by piece - or rather roll by roll - they bend the piece of sheet metal a little bit more until the workpiece finally reaches its desired shape. This is a very demanding task for the small rolls. Therefore, they must have very specific characteristics in order to display certain longevity and efficiency.

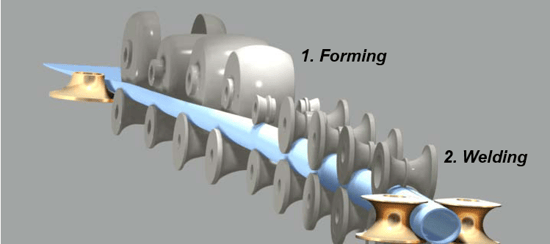

Image: schematic illustration of the roll forming process

Image: schematic illustration of the roll forming process

The three most important properties are:

- Wear resistance

The sheet strip is sliding directly on the roll surface and will be shaped. In the process, strong forces act on both the sheet metal and the rollers. Forming rolls made of an alloy that offers high hardness provide therefore a significantly increased lifetime, thanks to the increased wear resistance.

- Sliding properties

Another crucial characteristic that helps extend the service life of forming rolls is a good sliding property. Combined there are three movements happening at each forming roll. First is the forward movement of the sheet strip, as it is continuously rolled forward. Secondly, the shaping movement of the sheet strip, as it is continuously sliding in order to ultimately form its desired shape. These two movements combined result in the effective relative movement. Therefore, outstanding sliding properties are a must for forming rolls. - Low elongation

In order to provide a high shaping precision of the end product, the forming roll must be stable in its shape to guarantee the utmost accuracy. Therefore, a low elongation is the third important property that forming roll materials need to have.

Three different welding processes

At the end of the roll forming mill, a welding station is used to permanently join the two endings of the sheet metal together, so that the tube is closed. This can be done by three different welding processes, resulting in different requirements for the material of the welding rolls.

- High-frequency induction welding (HFI)

HFI is a welding process in which the heat source used to melt the joining pieces is obtained from high-frequency. It requires good sliding properties, high hardness, and permeability 1. For this operation, AMPCO® 25 is perfectly suited.

- Laser welding

Laser welding is used to join metals using a laser beam to form the weld. Besides good sliding properties and high wear resistance, welding rolls that are used for laser welding need to have great heat conductivity, and elongation is necessary. That’s why for this operation AMPCO® 21 or AMPCO® 25 are the right choices.

- TIG welding

TIG welding included the use of a non-consumable tungsten electrode to produce the weld. Basically, welding rolls that are used for TIG welding need to have the same properties as laser welding. Although, the elongation of the material can be slightly lower. Therefore, we suggest the use of AMPCO® 21 or AMPCO® 22 for this operation.

Image: Welding roll for HFI welding made of AMPCO® 25 (left), guiding and pressure rolls for laser welding made of AMPCO® 21 (right)

AMPCO® 25 – a unique copper alloy

AMPCO® 25 is a patented and extremely hard-grade performance alloy with exceptional mechanical properties, ideally suited for efficient production. It combines excellent compressive strength and good friction properties with excellent sliding and thermal transfer characteristics. These properties make AMPCO® 25 an ideal fit for forming rolls.

Want to learn more about metal forming and why aluminum bronze is the right choice for your deep drawing tools? Download our free technical paper «Material guide for each metal forming process » now.

.png?width=250&name=download-1500x1435%20(7).png)