Depending on the material in use and the required finishing precision, different techniques can be used in order to bend tubes. In our blogpost you'll get to know the most common methods.

Have you ever looked at a really complex bent tube and asked yourself, «Wow, how do you get such a perfect bend on a hard metal tube?» Well, we can! And that's exactly why we got to the bottom of it and went in search of the perfect bend.

In the process, we have discovered that there are multiple ways to bring a tube into its final shape. Which technique one chooses depends on various factors. These include the quality of the metal, the available resources, and ultimately the intended use of the end product. Basically, two different procedures can be distinguished. While cold forming is much more common, there is also the option of heat-supported forming.

Let’s take a closer look at some different types of tube bending:

Heat-supported forming

The following two variants use heat energy to trigger plastic deformation of the tube during bending. Heat-supported forming is commonly used to bend tubes made of polymers such as PVC, CPVC, and ABS.

-

Heat induction bending

Heat induction bending is a very efficient and precise bending technique and is used when cold forming reaches its limitations. For this purpose, the workpiece is heated to a temperature between 430°C – 1,200°C, depending on the material, and bent. After bending, the workpiece is quenched in the air or in a water jet.

-

Sand packing hot-slab bending

Sand packing hot-slab bending is an old bending process, but still in active use. The tube is filled with sand and the ends are fitted with a cap. In the furnace, the filled tube is heated to over 870°C and then the tube is fixed between pins and bent around these pins. Thanks to the sand, the tube retains its original cross-section.

Cold forming

Contrary to heat-supported forming, cold forming is carried out at room temperature. Cold forming techniques are commonly used when the tube to be bent is made of metal. These techniques include, among others:

-

Press bending

Press bending is probably the oldest industrial bending technique. Hereby, the pipe is placed and fixed on two counter rollers with a bend die up above. When pressure is applied, the bend die is pressed against the two counter-rollers. This motion forces the pipe inserted between the bend die and the counter-rollers to bend around the bend die.

Picture: Press bending machine

Picture: Press bending machine

-

Compression bending

Compression bending is similar to rotary draw bending, yet it is generally cheaper. However, the simpler set-up not only causes a reduction of the cost but also comes with some limitations. The use of a mandrel to support the inner diameter is not necessary in this case. Therefore, it can cause the outside surface to flatten slightly.

Picture: Compression bending machine

Picture: Compression bending machine

-

Roll bending

If you need to bend a tube with a large centerline radius, roll bending might be the best choice. The process consists of two stationary rotating rollers and a moving roller which is positioned in a triangular pattern. Roll bending offers various advantages: First of all speed and economy of scale. But also the ability to form complex shapes. Typically, roll bending finds application for large tubing components.

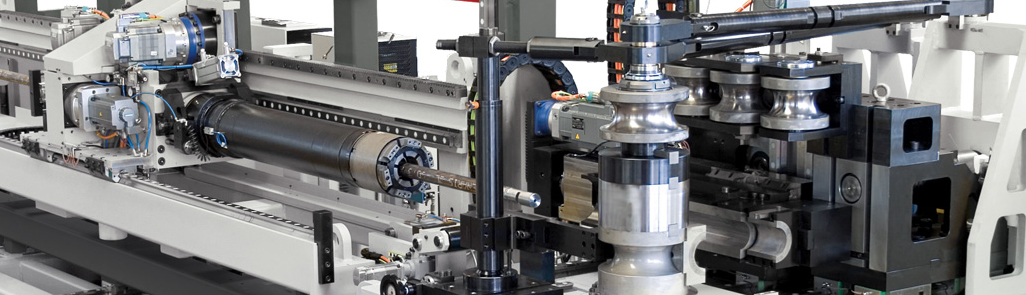

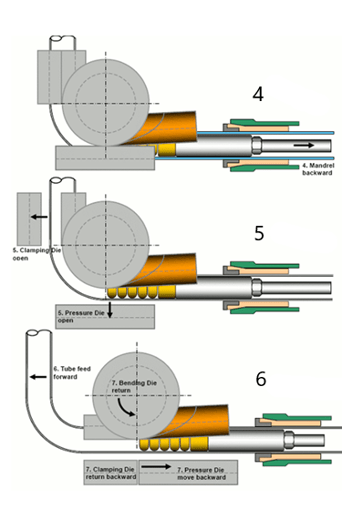

Rotary draw bending – an overview

The most commonly used process when bending tubes is rotary draw bending. It is the most precise type of bending, too. It involves a rotary draw machine, which bends the metal through a series of die sets with a consistent centerline radius. This technique is well suited for highly specific jobs and is used to bend tubes for products like roll cages, handrails, or handles.

Picture: Rotary draw bending process

But why exactly is rotary draw bending so precise? Two valuable components play a large part in this: mandrels and wiper dies. Mandrels are used to offer internal support to the tube during bending and therefore mitigate defects such as crinkling or flattening of the inner radius of the bent tube. On the other hand, wiper dies are used to stop wrinkling from occurring on the inside radius of the tube. The choice of material for wiper dies and mandrels can be crucial to the quality of the end result as well as the cost-effectiveness of the process. Here is where aluminum bronze can offer some major benefits in this metal forming process.

For further information about tube bending, you can download now a free copy of our technical paper «Advantages of copper-based alloys in tube bending»