The reddish-gold metal we call copper is the first metal that humans ever worked. It is primarily found in minerals, is very malleable and was first hardened by adding tin, creating the alloy we call bronze, after which an entire historical period is named. Annealed copper (H040) has a minimum hardness of 40HV and a minimum tensile strength 200 N/mm2 (R200). Fully cold worked copper (H110) has a hardness of 110HV minimum and a tensile strength of 360 N/mm² (R360) minimum. Copper is used mainly in electrical equipment such as wiring and motors nowadays, and when it comes to industrial machinery, heat exchangers are the main use of copper. Why exactly is that?

Copper in use for injection molds

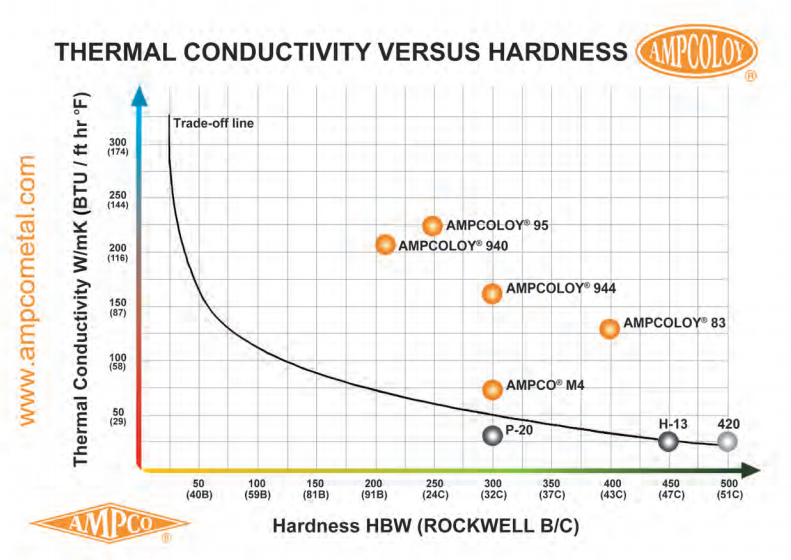

Machinery parts that are involved in heat exchange like injection molds need to be highly conductive, machinable and resistant to corrosion. Copper has a notable thermal conductivity of almost 400 (W/(m*K)) and a great electrical conductivity of 5.96×107 σ (S/m) at 20° Celsius. Thanks to its excellent thermal conductivity combined with its malleability, copper is the best choice for injection molds that there is. It can increase production speed by 15 - 40 % because it can be heated and cooled very quickly. The only problem is that with its great malleability comes a slight deficit in hardness. Therefore, copper is often mixed with other materials to make it stronger for different kinds of industrial uses, which results in considerably useful materials. These materials are not only highly conductive, they also do not produce sparks, are nonmagnetic and resistant to corrosion, which makes them usable for many different purposes.

Copper saves resources and is environmentally friendly

Copper is not only the ideal material for heat exchange and many other uses, it is also the material of the future, partly because it is used so frequently in renewable energy systems. According to the European Copper Institute, Copper consumption will rise by more than 40 % until 2035. It also helps that copper can be recycled without any loss of performance, which requires up to 85 % less energy than primary production.

In conclusion, it seems obvious that if you work in the industrial sector, copper should definitely be on your radar, especially if you work in the plastics industry. At AMPCO METAL, we have known about the advantages of copper since 1914. Ask us about copper and we will be happy to advise you about how it could benefit you and your company.

Get our Technical Paper «Advantages and disadvantages of copper beryllium in the manufacture of injection molds» for free.