What is additive manufacturing, and why does it matter today? Once used mainly for prototypes, it now drives full-scale production across industries. By building parts layer by layer, it enables designs and efficiencies that conventional methods cannot achieve.

Additive manufacturing, often referred to as 3D printing, is a method of producing components by adding materials incrementally, based directly on digital designs. Unlike subtractive methods such as cutting, milling, or casting, this approach removes many of the limitations of conventional production and opens the door to new design possibilities.

By enabling lightweight structures, complex geometries, and highly tailored parts, additive manufacturing has grown from a prototyping tool into a proven production technology. For engineers and professionals across aerospace, automotive, medical, and tooling industries, understanding what is additive manufacturing is now essential for recognizing where it can add real value in modern production.

What is Additive Manufacturing and How Does it Work

Additive manufacturing works by building components in successive layers from a digital design file. Instead of removing material, as in machining, or pouring it in dies, as in casting, the process adds only the material needed. This makes it possible to create complex geometries that would be difficult or even impossible with traditional methods.

In metal additive manufacturing, fine alloy powders are melted together using processes such as Powder Bed Fusion (PBF-LB) or Direct Energy Deposition (DED). Each layer is fused or deposited with precision until the final part takes shape. The result is a component with performance properties tailored to demanding industrial applications.

For engineers, the value lies in design freedom, reduced waste, and the ability to optimize parts for specific performance needs. This shift from conventional methods allows teams to develop new solutions that improve both efficiency and functionality.

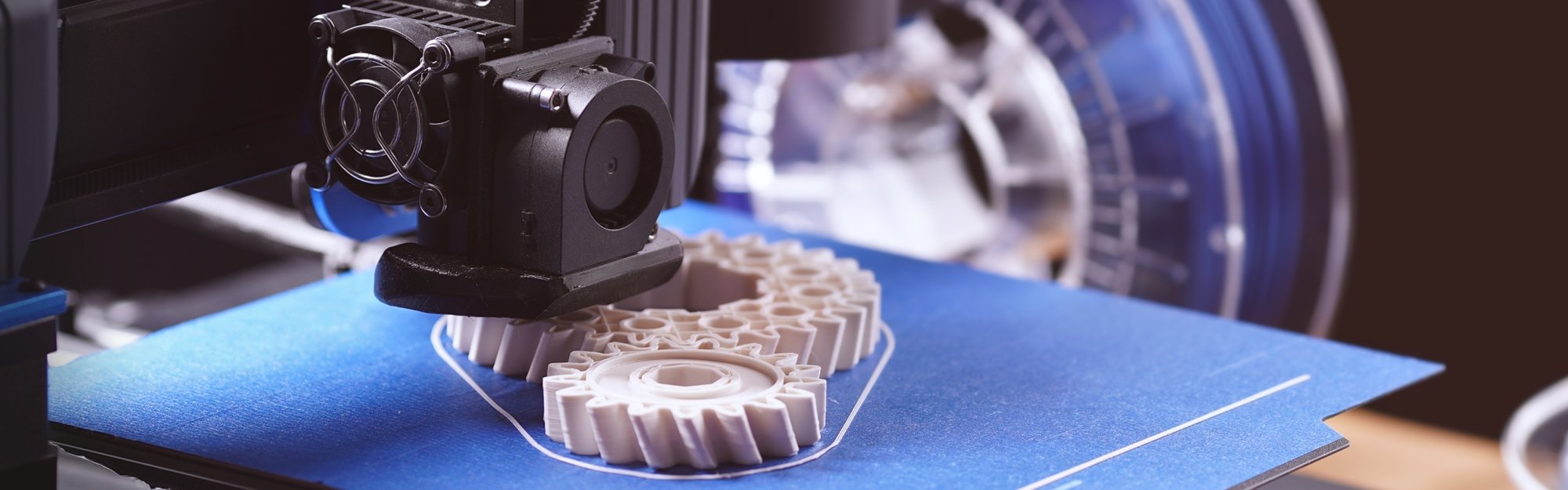

Standard use of an automatic 3d printer for plastic printed parts

Standard use of an automatic 3d printer for plastic printed parts

Key Benefits Driving Adoption

One of the most important advantages of additive manufacturing is design consolidation. Instead of assembling multiple parts, engineers can produce a single integrated component, reducing assembly steps and potential points of failure, like the case with inductors for hardening systems. This not only improves reliability but also streamlines production.

Flexibility is another driver. With additive manufacturing, digital files can be adjusted quickly, enabling customization without the need for expensive tooling changes. This makes it easier to adapt designs to specific customer requirements or to rapidly iterate prototypes into production-ready parts.

Finally, additive manufacturing allows for localized production, closer to where components are needed. This reduces reliance on complex supply chains and helps industries respond faster to changing demands. For many companies, these strategic advantages are just as valuable as improvements in material use or production speed.

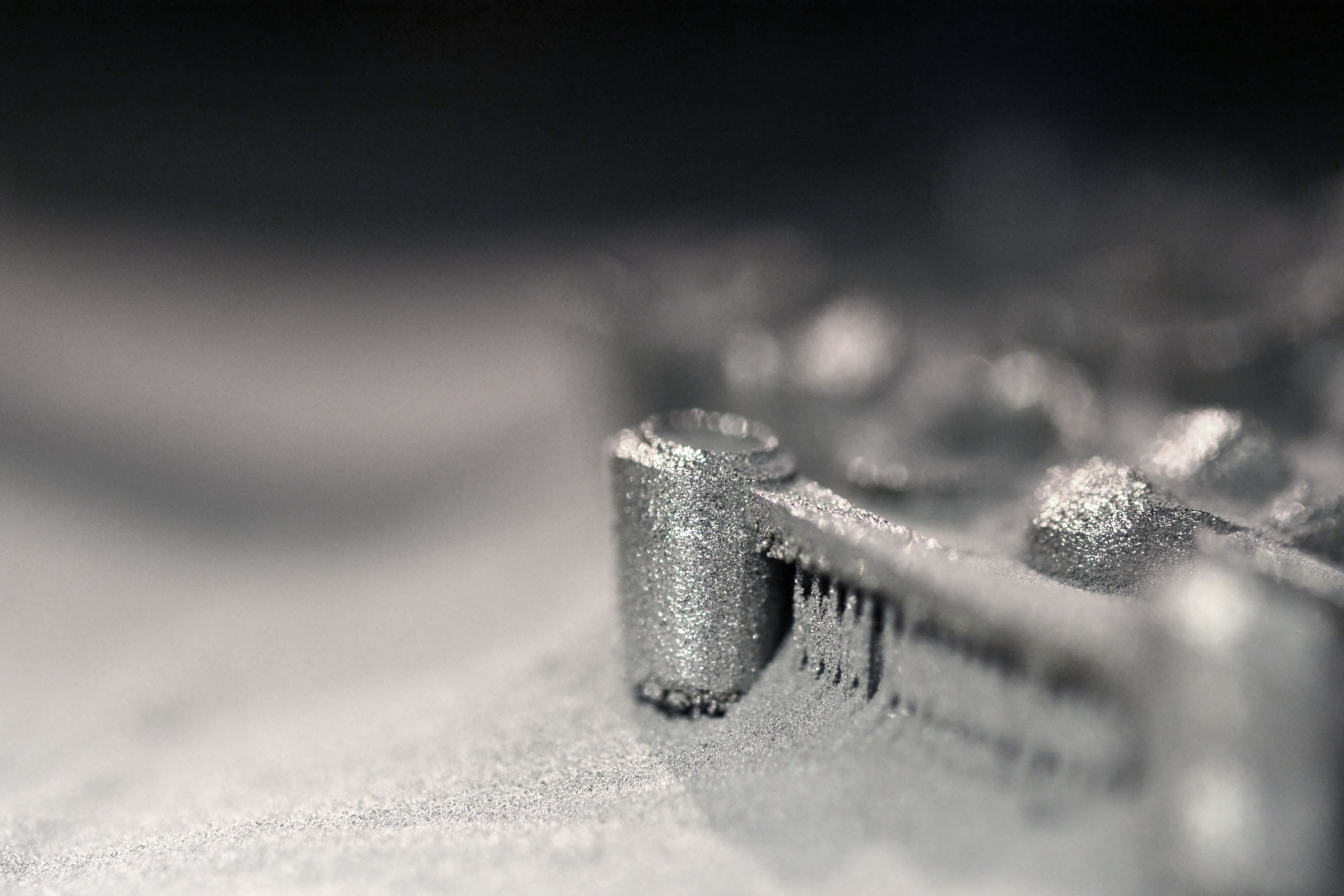

Printing platform with a 3d printed object covered in metallic powder

Printing platform with a 3d printed object covered in metallic powder

Where It’s Being Used Today

Additive manufacturing is now routine in production settings, not just prototyping. Industries apply it where geometry, thermal management, and fast iteration matter most.

- Aerospace

Lightweight structural brackets, complex ducting, and cooled components for demanding thermal loads. - Automotive

Tooling inserts and production parts that benefit from part consolidation and rapid updates. - Plastic injection molding

Conformal‑cooled inserts that shorten mold cycle times and improve temperature control. - Induction equipment

Custom copper alloy inductors tailored to precise heating profiles and internal cooling paths. - Heat exchangers

Compact designs with intricate internal passages for efficient heat transfer. - Medical and healthcare

Patient‑specific guides and components that require customization and clean internal geometries.

These applications show how design flexibility translated to measurable production gains.

Final Thoughts

Additive manufacturing has moved far beyond its early role as a prototyping tool. It is now a proven method for producing complex, reliable parts across a wide range of industries. By enabling new design possibilities, reducing production steps, and supporting faster innovation, it has become an essential technology in modern manufacturing. For engineers and technical professionals, understanding what is additive manufacturing covers the first steps toward recognizing where it can deliver real value.

As additive manufacturing continues to expand, materials will play an increasingly decisive role in performance. AMPCO’s expertise in engineered copper alloys positions it to support industries where electrical or thermal conductivity, mechanical strength, durability, and precision are critical. Exploring these possibilities further and expanding knowledge, for example via our Academy, can help companies identify where additive solutions fit into their production strategies.