Weld defects can turn a stable resistance welding process into scrap, rework, and downtime. Our article explains how common defects form, what typically causes them, and practical steps to prevent them.

Why Weld Defects Happen in an Otherwise Stable Process

In resistance welding, defects rarely come from a single “wrong setting.” More often, they appear when small process shifts stack up: a change in surface condition, gradual electrode wear, inconsistent fit-up, cooling issues, or variation in force and current delivery. The result can be welds that look acceptable on the surface but fail strength, consistency, or appearance requirements in production.

Preventing weld defects starts with understanding what the defect indicates. Some point to insufficient heat at the interface, others to excessive heat, unstable contact resistance, or poor containment of the molten zone. This article breaks down how common weld defects show up, what typically causes them, and the practical checks and controls that help keep resistance welding stable over long runs.

Common Weld Defects in Industrial Production

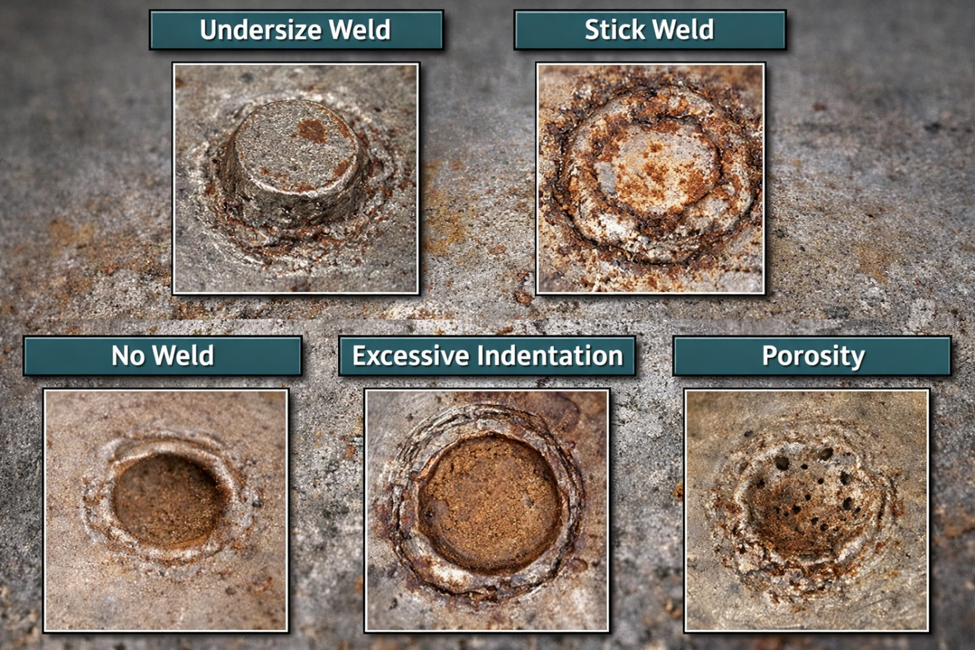

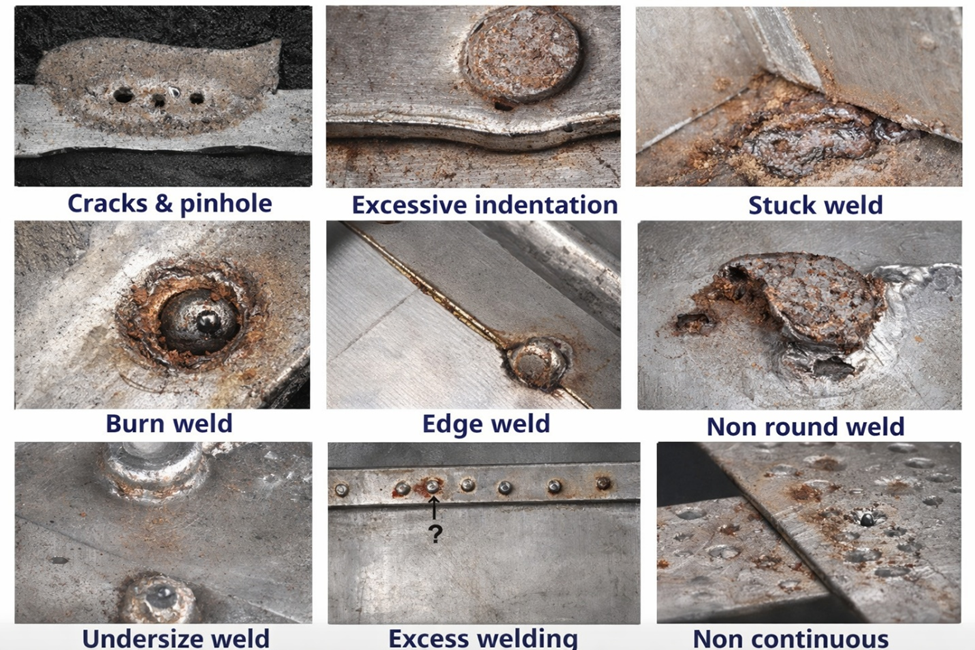

In industrial resistance welding, defects usually show up in a few repeatable ways. Some are visible right away. Others only appear during destructive testing, fatigue testing, or later assembly steps. Knowing the “typical signatures” helps teams troubleshoot faster and avoid chasing the wrong variable.

- Expulsion and excessive spatter: Molten metal is forced out of the joint during the weld. This often leaves visible ejection marks and inconsistent nugget formation and can accelerate electrode wear.

- Undersized weld nugget: The weld forms, but the nugget is too small to meet strength requirements. This can lead to low peel or shear strength and early joint failure under load.

- Intermittent welds or inconsistent strength: Weld quality varies from part to part, even with the same nominal settings. This is one of the most costly issues because it increases inspection, rework, and uncertainty.

- Surface marking and indentation: Excessive electrode imprinting or deformation of the part surface. In cosmetic or coated parts, this can become a rejection criterion even if strength is acceptable.

- Electrode sticking or pickup: Material transfers to the electrode tip, which changes contact conditions and can quickly destabilize the process. It also increases dressing frequency and downtime.

- Cracks in or around the weld zone: Depending on material and part design, cracking can appear in the fused zone or nearby areas. This is less common than expulsion or undersized nuggets, but it is high risk when it occurs.

Examples of resistance welding defects

Common Causes of Weld Defects

Most weld defects are the result of heat being generated in the wrong place, at the wrong rate, or with poor repeatability. In resistance welding, that usually comes back to a short list of drivers: current, time, force, contact condition, electrode state, and cooling. Below is how they typically connect to the defect patterns you see in production.

- Incorrect heat input (current and time):

- Too little heat often leads to undersized nuggets, low strength, or “cold” welds.

- Too much heat increases the likelihood of expulsion/spatter, excessive marking, and faster electrode degradation.

- Unstable contact resistance (surface condition and fit-up):

Oils, oxides, coatings, scale, and inconsistent part fit-up change resistance at the interface. That shifts where heat forms and can create intermittent weld strength, scattered expulsion events, or unpredictable appearance. - Force issues (too low, too high, or inconsistent):

Force controls real contact area and current density.- Low force can increase interface resistance and promote expulsion and instability.

- High force can reduce resistance at the interface and contribute to small nuggets if heat cannot concentrate where it’s needed. Inconsistent force often shows up as part-to-part variation.

- Electrode wear, geometry drift, and alignment:

As tips mushroom, misalign, or lose their intended shape, current density and pressure distribution change. This commonly drives marking, inconsistent nugget formation, and increased risk of pickup and sticking. - Electrode material behavior:

Electrode alloys affect conductivity, hot strength, and resistance to deformation and pickup. If the electrode material softens too quickly or deforms under heat and load, the process can drift faster, leading to more frequent dressing and higher defect rates. High-copper alloys such as AMPCOLOY® are often selected in electrode and electrode-component applications where stable current transfer and heat removal support more consistent welding over long runs. - Cooling and heat buildup over time:

Even when parameters are correct at startup, poor cooling can allow electrode and tooling temperatures to climb. That can change contact behavior, increase pickup, and make defects appear later in the shift, often as rising marking, spatter, and inconsistent strength.

Resistance welding defects occurring in an industrial setting

How to Prevent Weld Defects

Prevention in resistance welding is mostly about keeping the process stable over time. The goal is to control heat generation at the joint interface and avoid drift caused by surfaces, electrodes, force delivery, and cooling. These steps are practical, production-friendly, and apply across most resistance welding setups.

- Start with a stable weld schedule, then protect it:

Establish a validated baseline for current, time, and force, then control changes. Avoid adjusting multiple settings at once during troubleshooting. Small, measured changes make root causes easier to confirm. - Control surfaces and fit-up before you chase settings:

Clean contact surfaces when required and keep upstream processes consistent. Oils, oxides, coatings, and scale can change contact resistance enough to create defects even when the weld schedule is correct. Verify part fit-up, alignment, and clamping consistency, especially in stacked or formed components. - Keep force delivery consistent:

Confirm that the force shown on the controller matches what reaches the parts. Inspect mechanical wear in arms, pivots, guides, and cylinders. Inconsistent force is a common cause of part-to-part variation that looks like a “current problem” but isn’t. - Manage electrodes as a controlled consumable:

Track electrode tip shape, alignment, and condition. Use a defined dressing plan based on parts per tip, not just visual checks. Replace electrodes before geometry drift becomes a process variable. If pickup is occurring, address it early, because it can destabilize the process quickly. - Select electrode materials for the job, not just for initial cost:

Electrode material affects how well current transfers and how efficiently heat is removed. In applications where heat buildup, deformation, or pickup drives defects, high-copper alloys such as AMPCOLOY® can be used for electrodes and electrode components to support stable performance and longer consistency between maintenance intervals. - Verify cooling performance, not just water flow:

Confirm that cooling paths are clean and unobstructed and that the system maintains stable temperatures during production. Heat buildup over a shift can change electrode behavior and shift weld results even if the settings are unchanged. - Use simple monitoring to catch drift early:

Trend basic indicators like weld current, resistance, force, and tip dress counts when available. Even without advanced systems, tracking defect types by station and time of shift can point quickly to electrodes, cooling, or surface variation.

Final Thoughts

Weld defects are rarely random. In most cases, they trace back to unstable heat input, shifting contact resistance, inconsistent force delivery, electrode wear, or gradual heat buildup in the tooling. The fastest path to fewer defects is a controlled baseline, disciplined electrode and surface management, and basic checks that prevent drift before it shows up as scrap or rework.

For more practical guidance on welding materials, process stability, and tooling performance, explore the technical articles on the AMPCO Academy, where we share application-focused insights for manufacturing and engineering teams.