3D printing challenges in industrial production often stem from the limitations of materials rather than the process itself. AMPCO copper alloys are engineered to overcome these barriers, providing the electrical and thermal performance and mechanical stability required for consistent, high-quality results.

Additive manufacturing has become a proven production method but adopting it at an industrial scale requires solving challenges that go beyond basic printability. Thermal management, material stability, and repeatability are critical factors that determine whether a component can perform under real operating conditions.

AMPCO copper alloys are developed with these requirements in mind. By combining high conductivity with mechanical strength, they address long-standing barriers in printing copper-based materials and ensure that additive manufacturing delivers parts capable of consistent use in demanding environments.

Common 3D Printing Challenges in Industrial Production

While additive manufacturing has advanced significantly, several challenges remain for companies aiming to use it in critical production environments:

- Thermal management: Many alloys cannot transfer heat effectively, leading to slower cooling in molds, unstable heating in inductors, or inefficient energy transfer in exchangers. Poor conductivity often limits component performance and service life.

- Material processing difficulties: Copper’s reflectivity and rapid heat dissipation make it difficult to process with laser-based systems. Without precise powder characteristics and controlled parameters, builds can suffer from porosity, incomplete fusion, or low part properties.

- Mechanical reliability: Parts that lack sufficient strength or ductility may deform under load or fail during thermal cycling. This is particularly problematic in aerospace, tooling, and high-energy systems where stability is essential.

- Consistency and repeatability: Success in a single build is not enough. Industrial adoption requires predictable results across multiple runs, with properties that remain within defined ranges for every component produced.

These are exactly the challenges that highlight why material selection is central to the success of additive manufacturing and why specialized alloys are required to move beyond prototypes and into full-scale production.

-Oct-27-2025-05-48-04-5894-PM.jpg?width=1080&height=1350&name=New%20Instagram%201080x1350%20(6)-Oct-27-2025-05-48-04-5894-PM.jpg)

A finished component made via additive manufacturing

How AMPCO Provides Targeted Solutions to 3D Printing Challenges

For additive manufacturing to move into full production, materials must integrate seamlessly with established workflows. AMPCO copper alloys are designed with this requirement in mind, ensuring that each stage of the process, from powder handling to post-treatment, supports consistency and reliability.

- Process compatibility: AMPCO alloys perform reliably in both Powder Bed Fusion (PBF-LB) and Direct Energy Deposition (DED), allowing manufacturers to choose the process best suited to their application without compromising material performance.

- Powder reliability: Gas-atomized powders are produced with tight control over particle size and purity. This consistency across batches ensures repeatable build quality and reduces variation in key properties such as conductivity and strength.

- Predictable post-processing: Tailored heat treatments enable us to customize hardness, ductility, and yield strength. Standardized procedures ensure that parts meet specifications with minimal variation, enabling smoother integration into production workflows.

- Repeatability in production: With controlled powder characteristics and reliable post-treatment, AMPCO alloys deliver uniform properties across multiple runs, reducing scrap rates and ensuring confidence in scaling additive manufacturing to industrial volumes.

By aligning material performance with the requirements of additive workflows, AMPCO alloys help manufacturers transition from one-off builds to dependable series production.

Performance Insights from Demanding Use Cases

AMPCO copper alloys demonstrate their value not only in technical performance but also in the factors that determine whether additive manufacturing can be adopted at scale. Their role extends into certification, hybrid workflows, lifecycle efficiency, and supply chain readiness.

- Qualification and certification readiness

Consistent material properties, including density, conductivity, and tensile strength, fall within narrow, predictable ranges. This makes testing and certification for aerospace, energy, and other regulated industries more straightforward, reducing barriers to qualification. - Hybrid manufacturing integration

AMPCO alloys can be used in combination with subtractive techniques, such as machining or welding, to create hybrid components. This allows features to be additively manufactured onto machined bases, enabling both design flexibility and robust structural assurance. - Lifecycle data and maintenance impact

Proven durability reduces the frequency of replacements and extends service intervals. In practice, this means lower maintenance requirements, smaller tooling inventories, and more predictable equipment availability, all measurable benefits for production managers. - Supply chain and on-demand manufacturing

Reliable powder quality and repeatable processing make it possible to print replacement parts where they are needed. By enabling localized production, AMPCO alloys reduce dependence on global supply chains and shorten lead times for critical components.

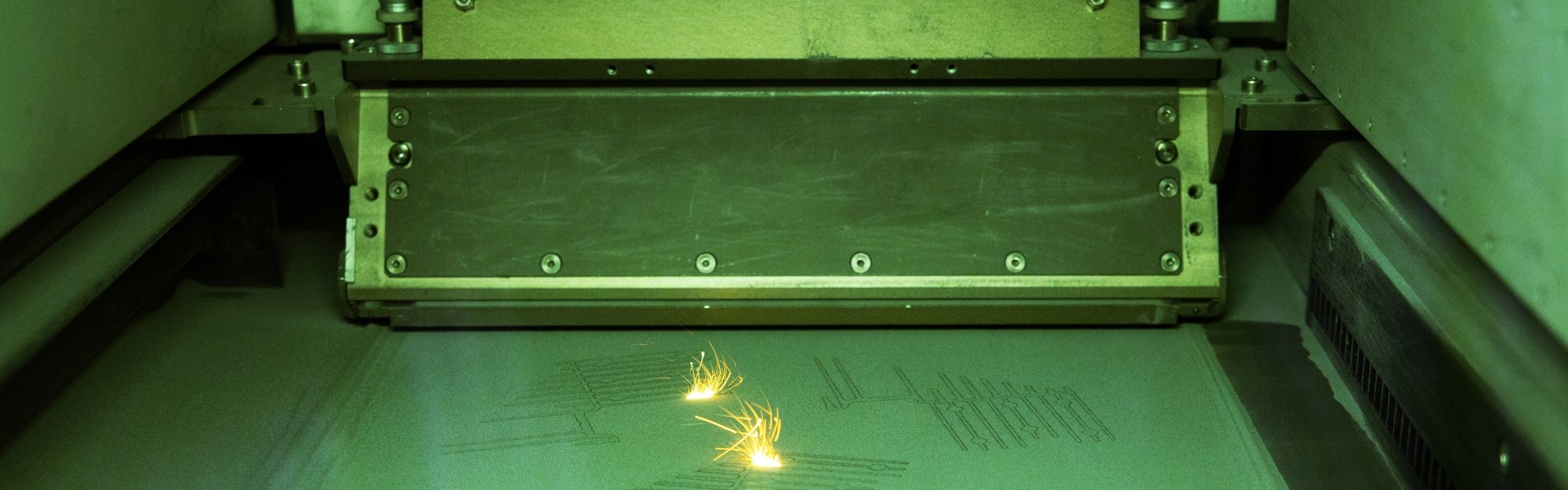

-Oct-27-2025-06-22-18-6692-PM.jpg?width=1080&height=1350&name=New%20Instagram%201080x1350%20(5)-Oct-27-2025-06-22-18-6692-PM.jpg)

The surface of the printed parts is of very high quality and precise

Final Thoughts

The shift from experimental builds to reliable industrial production depends on solving material-specific challenges. AMPCO copper alloys demonstrate that these barriers, from processing difficulties to operational reliability, can be overcome with engineered solutions that deliver measurable results. Their consistency, integration with established workflows, and proven durability position them as a dependable choice for manufacturers adopting additive manufacturing.

For professionals who want to explore these solutions further, the AMPCO Academy provides additional resources on materials and processes for additive manufacturing. AMPCO METAL also provides a full scale of services for additive manufacturing using copper alloys. From materials and designs to production and optimalization of 3D printed parts and processes. Our long-term expertise and professionals are at your disposal.