Additive manufacturing technology is evolving beyond its early role, with new trends shaping how industries use it today. Advances in metal processes, performance-driven materials, and application-specific design are pushing this technology toward broader adoption and lasting industrial impact.

Additive manufacturing technology is moving into a new era defined by scale, performance, and design innovation. Instead of being limited by early technical barriers, it is now developing in ways that open doors to industrial adoption at a much larger scope.

For engineers and professionals, the most important question is how this technology will evolve next. Key areas such as process maturity, advanced materials, design strategies and integrations into standards are shaping its trajectory and determining the role it will play in tomorrow’s manufacturing landscape.

Expansion of Metal Additive Manufacturing Technology and Process Maturity

One of the most significant developments in additive manufacturing technology is its growing maturity in metal production. Processes like Powder Bed Fusion (PBF-LB) and Direct Energy Deposition (DED) are no longer experimental, but are being refined for consistent, repeatable results in industrial environments.

As process stability improves, build sizes are increasing, surface quality is getting closer to machining standards, and production runs are becoming more economical. This shift makes it possible for manufacturers to move beyond prototypes and one-off parts toward series production, where reliability and repeatability are critical.

For industries such as aerospace, automotive, tooling, and energy, this expansion means metal additive manufacturing is not only viable but increasingly competitive with conventional methods. As systems continue to mature, technology is positioned to play a central role in high-performance applications where precision and efficiency matter most.

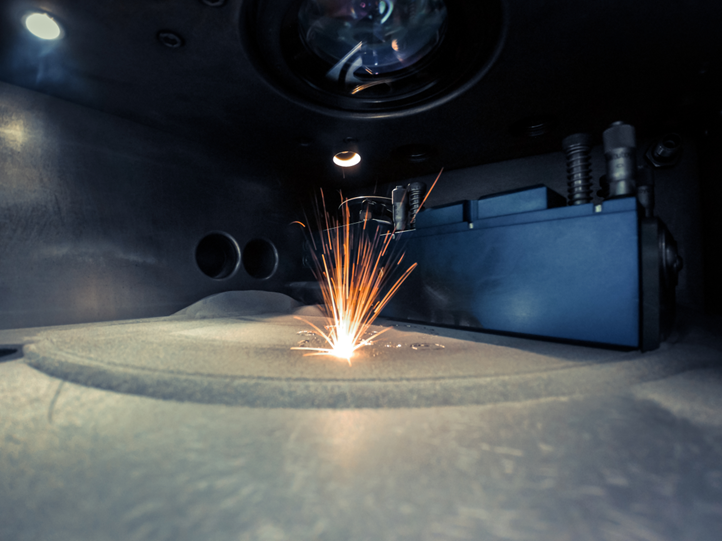

Metal laser sintering – powder bed fusion

Smarter Materials for Better Performance

The evolution of additive manufacturing technology is closely tied to the materials used. Early applications often relied on adapting existing alloys, but today, engineered materials are being developed specifically for additive processes. These tailored alloys provide higher purity, controlled powder characteristics, and performance properties that traditional options cannot consistently achieve.

Copper-based alloys are a prime example. Their high thermal conductivity, electrical conductivity and strength make them well-suited for applications such as conformal-cooled mold inserts, inductors, and heat exchangers. With powders optimized for additive manufacturing, engineers can now achieve both functional performance and processing reliability.

Key material advantages include:

- High thermal conductivity for efficient heat management.

- High electrical conductivity close to pure copper

- Strength and hardness for durability under loads.

- Consistent powder quality to ensure reliable processing.

- Balanced properties that extend component life in demanding environments.

This material-focused progress is one of the clearest signals that additive manufacturing technology is maturing into a dependable solution for production.

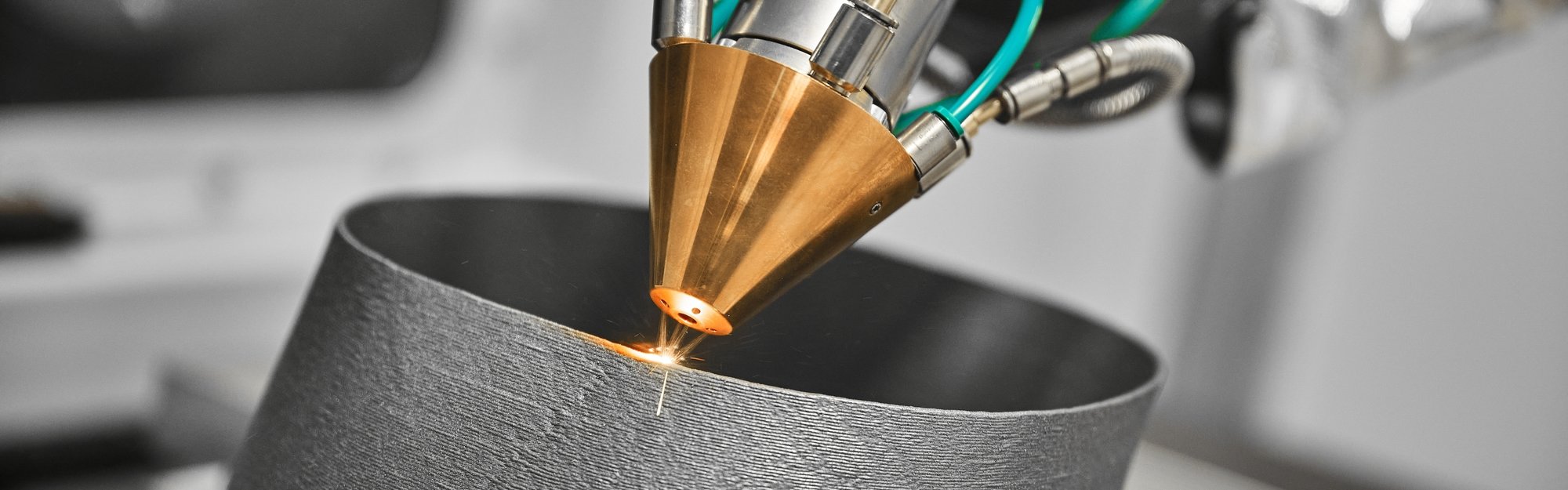

Finishing details applied by laser cladding using metal powder

Finishing details applied by laser cladding using metal powder

Design for Additive and Application-Specific Growth

As additive manufacturing technology advances, design strategies are evolving to take full advantage of its capabilities. Instead of simply recreating parts made for traditional methods, engineers are embracing design for additive manufacturing (DfAM), an approach that is intended to optimize components for the strengths of this technology.

This shift allows for design features such as:

- Conformal cooling channels that improve thermal management.

- Lightweight lattice structures that reduce weight without compromising strength.

- Part consolidation that reduces assembly steps and potential failure points.

Application-specific growth is also accelerating. From aerospace components exposed to extreme conditions, to mold inserts that improve cycle times, the ability to design precisely for end-use needs ensures that additive manufacturing delivers tangible benefits. By combining new design strategies with smarter materials and mature processes, industries are creating solutions that would be impossible with conventional production methods.

Final Thoughts

Additive manufacturing technology is entering a stage where process maturity, material innovation, and advanced design are coming together to unlock new possibilities. What was once considered a specialized tool is becoming a reliable part of mainstream production, delivering value across industries.

For engineers and decision-makers, following these trends is essential to stay competitive. The way processes evolve, materials improve, and designs adapt will determine how quickly additive manufacturing technology becomes a cornerstone of modern industrial practice.

AMPCO supports this evolution by providing engineered copper alloy powders as well as its own printers, all designed for the unique demands of additive processes. For companies exploring new opportunities, understanding the trends and the materials that drive them is the first step toward identifying where additive manufacturing technology can deliver the greatest impact. You can also read more about the future of many industries on our Academy.