Additive manufacturing applications succeed or fail based on the materials behind them. AMPCO copper alloys have proven their value in real production settings, delivering the thermal conductivity, durability, and reliability required to keep critical components performing under demanding conditions.

Additive manufacturing has reached a point where performance is measured not only by the complexity of the designs it can produce, but also by how well those parts operate in real conditions. Industries such as plastic processing, aerospace, and energy now demand materials that can manage heat, resist wear, and maintain precision under load.

AMPCO copper alloys meet these demands by combining high conductivity, good corrosion resistance with mechanical strength, making them ideal for applications where thermal control and durability are critical. Their use in additive manufacturing demonstrates how engineered alloys can bridge the gap between printing feasibility and proven industrial performance.

Proven Additive Manufacturing Applications Across Key Industries

In additive manufacturing, reliable performance depends on repeatability. A material must not only produce a single successful part but also deliver the same properties across multiple builds. Without this consistency, large-scale industrial use is not feasible.

AMPCO copper alloys are designed to provide this stability. Powder characteristics such as particle size distribution, purity, and oxygen levels are carefully controlled, ensuring predictable conductivity and mechanical strength. Post-processing methods are applied to adjust hardness, ductility, and yield strength and to keep them within defined ranges, so parts meet specifications with every run.

For industries where downtime and scrap directly affect cost and productivity, this level of control reduces variation, lowers rejection rates, and confirms that additive manufacturing can be scaled reliably. The ability to reproduce the same results in production is what turns additive manufacturing from an experimental tool into an industrial solution.

Why AMPCO Copper Alloys Deliver Measurable Performance

The performance of additively manufactured copper parts depends on the interaction between material properties and processing conditions. AMPCO alloys are engineered to maintain high thermal and electrical conductivity while achieving the mechanical strength required for demanding industrial use.

Controlled powder production ensures spherical particles with a narrow size distribution, which improves flowability and melting behavior during printing. Low oxygen levels preserve conductivity, while thermal post-processing under inert gas enables us to adjust hardness and tensile properties. The result is parts that combine conductivity values above 50 MS/m with yield strengths exceeding 250 N/mm², depending on the alloy and heat treatment applied.

This balance of thermal performance and mechanical reliability allows components such as mold inserts, inductors, heat exchanger and aerospace parts to operate under continuous load without degradation. The consistency of these results across multiple builds demonstrates that AMPCO alloys are not only compatible with additive processes, but are also optimized for them.

-Oct-27-2025-02-52-03-5544-PM.jpg?width=1080&height=1350&name=New%20Instagram%201080x1350%20(5)-Oct-27-2025-02-52-03-5544-PM.jpg)

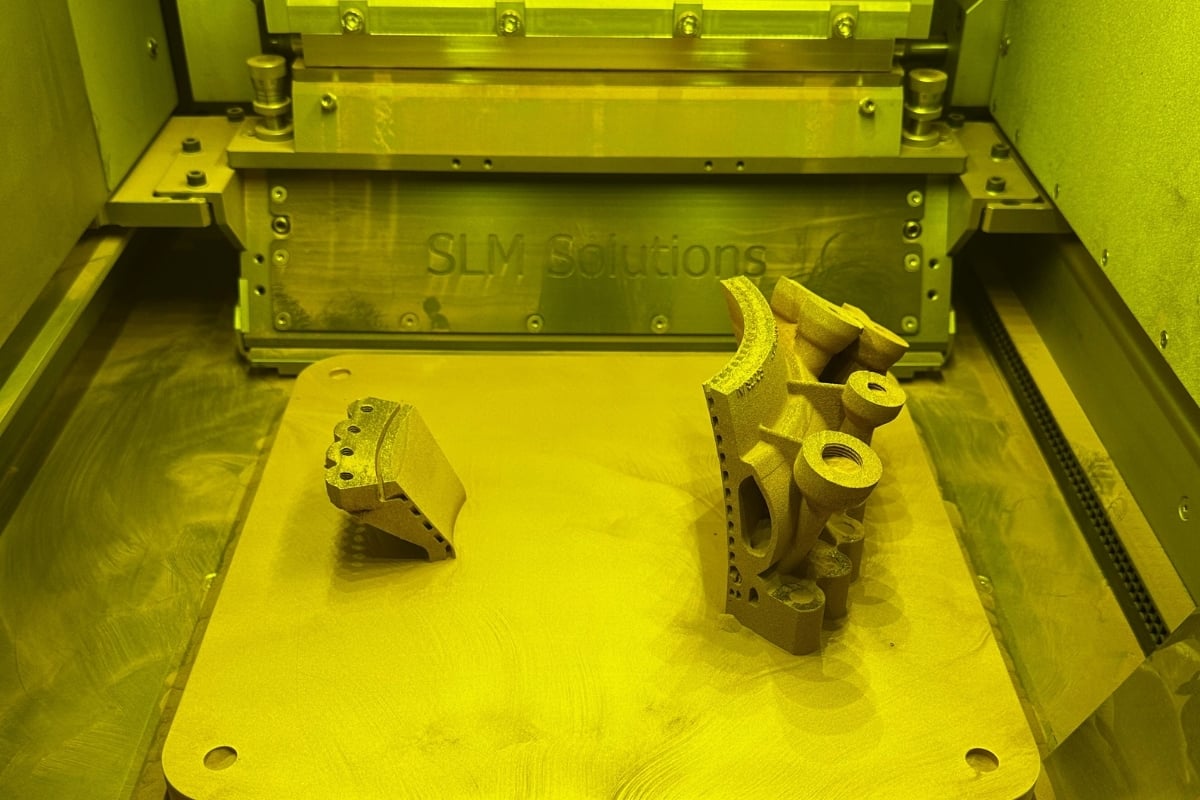

Powder bed fusion additive manufacturing in practice

Key Takeaways from Industrial Use of AMPCO in Additive Manufacturing Applications

Industrial use of AMPCO copper alloys in combination with additive manufacturing has confirmed that measurable benefits are achieved when material properties align with the requirements of the application beyond. High conductivity ensures efficient thermal management, while carefully controlled powder and post-processing parameters provide mechanical stability. These factors directly influence production efficiency, component longevity, and overall cost.

Key benefits observed in production environments include:

- Reduced cycle times: The superior heat transfer of AMPCO copper alloys accelerates cooling in mold inserts. Faster and more uniform temperature control shortens injection molding cycles and improves product quality and dimensional stability in plastic parts.

- Extended component life: Post-processed alloys retain both strength and ductility, preventing cracks and deformation under load. In inductors, monolithic designs remove weak soldered joints, significantly reducing thermal fatigue and extending service intervals.

- Lower rejection rates: Spherical powders with narrow particle size distribution ensure consistent melting behavior during PBF-LB and DED processes. Stable powder flow minimizes defects such as porosity, leading to higher print rates.

- Decreased downtime: Controlled heat treatment under inert gas produces repeatable hardness and yield strength, meaning components maintain performance over long operating periods. This reduces unscheduled maintenance and keeps equipment running longer.

- Improved cost-per-part: By combining conductivity with strength, AMPCO alloys allow for optimized part geometries and reliable operation, lowering scrap, extending service life, and reducing the frequency of replacements.

These technical advantages demonstrate that the benefits of AMPCO alloys are not theoretical but proven in industrial settings. The ability to deliver both material performance and process reliability makes them an essential enabler of additive manufacturing at scale.

Finished 3-D printed parts

Finished 3-D printed parts

Final Thoughts

The performance of additive manufacturing ultimately depends on materials that can meet industrial requirements for consistency, durability, and efficiency. AMPCO copper alloys have demonstrated that they are not only suitable for additive processes, but capable of delivering repeatable results across demanding applications. By combining reliable powder properties with tailored post-processing, they provide stable performance in production environments where reliability is critical.

For readers interested in exploring these results in greater depth, additional resources are available through the AMPCO Academy, which provides technical insights on additive manufacturing and alloy performance. AMPCO METAL also provides a full scale of services for additive manufacturing using copper alloys. From materials and designs to production and optimalization of 3D printed parts and processes. Our long-term expertise and professionals are at your disposal.