Surface quality is one of the most critical performance factors in deep drawing. AMPCO® Aluminum Bronze helps achieve superior surface finishes on deep drawn steel components by minimizing friction, preventing galling, and maintaining stable tool conditions throughout production.

Surface finish plays a decisive role in the quality and appearance of deep drawn steel components. Even minor imperfections on tool surfaces can transfer directly to the formed sheet, resulting in scratches, dull areas, or uneven textures that require costly rework. Maintaining a clean, stable contact surface throughout each forming cycle is therefore critical for achieving high-quality end products.

AMPCO® Aluminum Bronzes provide a proven solution to this challenge. Their excellent polishability, anti-galling properties, and good thermal conductivity help preserve smooth tool surfaces even under heavy mechanical load. By combining durability with superior sliding behavior, AMPCO® 25 and AMPCO® 26 enable manufacturers to achieve the consistent surface quality demanded in automotive, appliance, and industrial applications.

Why Surface Quality is Crucial in Deep Drawn Steel

In deep drawn steel components, the quality of the surface defines both functionality and appearance. Scratches, drag marks, or uneven textures are not only visual defects but can also weaken protective coatings and reduce corrosion resistance. For manufacturers supplying to industries such as automotive or household appliances, where flawless surfaces are essential, tool condition directly determines production success.

These surface imperfections often stem from adhesion between the sheet and the tool during forming. As steel slides over the die and punch, friction and heat can cause galling, resulting in metal pickup and roughened surfaces. Once this occurs, even minor tool damage is quickly replicated across each part produced. Maintaining smooth, clean tool surfaces and stable friction conditions is therefore essential to achieving a uniform finish and consistent part quality.

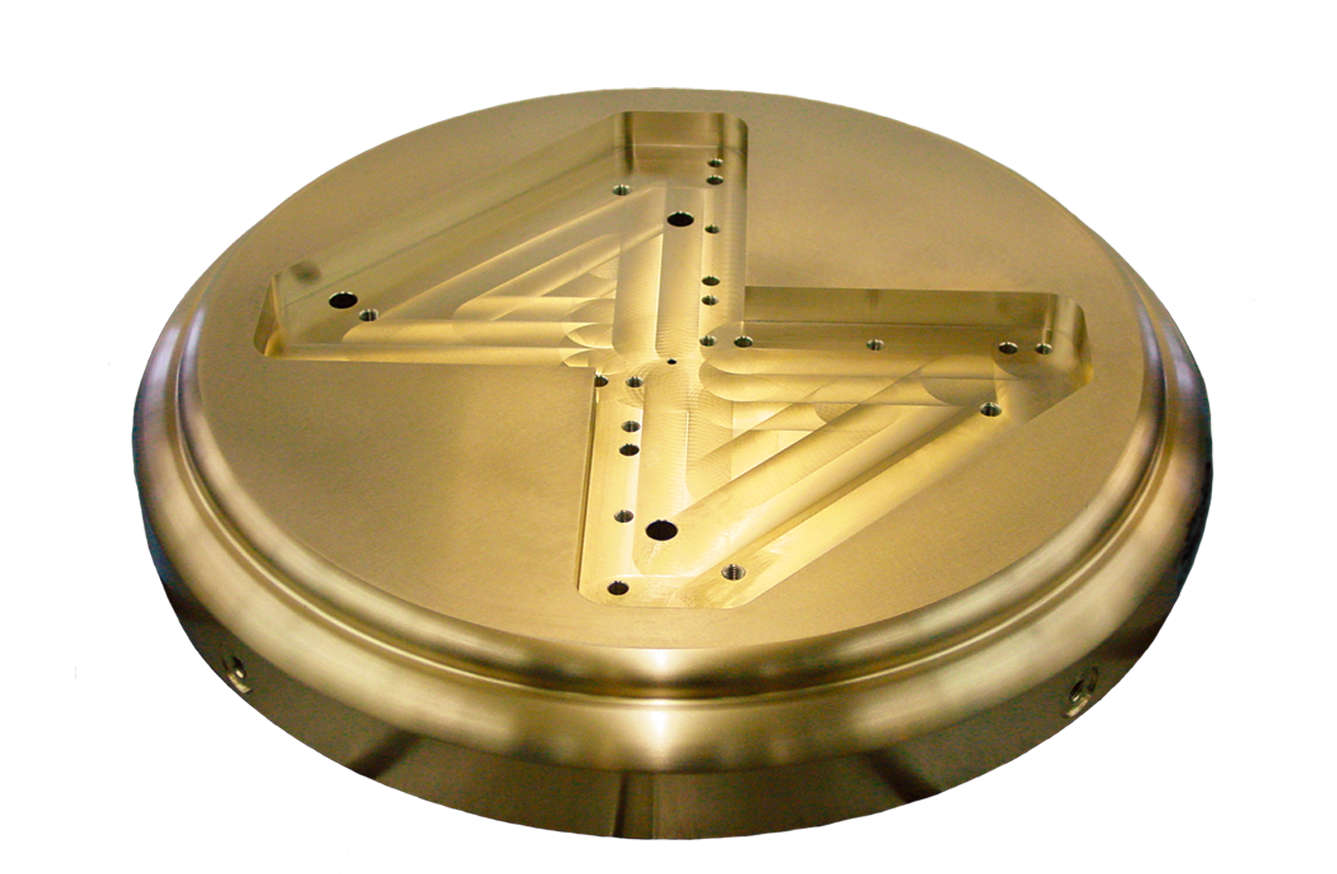

AMPCO® Aluminum Bronze deep drawing punch for washing machine drums

AMPCO® Aluminum Bronze deep drawing punch for washing machine drums

The Role of AMPCO Alloys in Achieving Superior Surface Finish

AMPCO® Aluminum Bronzes are specifically engineered to prevent galling and maintain clean tool surfaces, even during continuous high-pressure forming. Their fine-grained microstructure and low-friction properties reduce adhesion between the sheet and the tool, ensuring smooth sliding contact. This helps eliminate metal pickup and surface defects, allowing for uniform and visually flawless deep drawn steel parts.

Polishability is another key advantage. Both AMPCO® 25 and AMPCO® 26 can be machined and polished to a mirror finish, which directly translates to improved part appearance and reduced need for post-processing. Their good thermal conductivity also stabilizes tool temperature, preventing localized overheating that can dull or damage tool surfaces over time.

By maintaining optimal surface conditions throughout production, AMPCO® alloys help manufacturers deliver consistent part quality while minimizing rework, tool maintenance, and downtime.

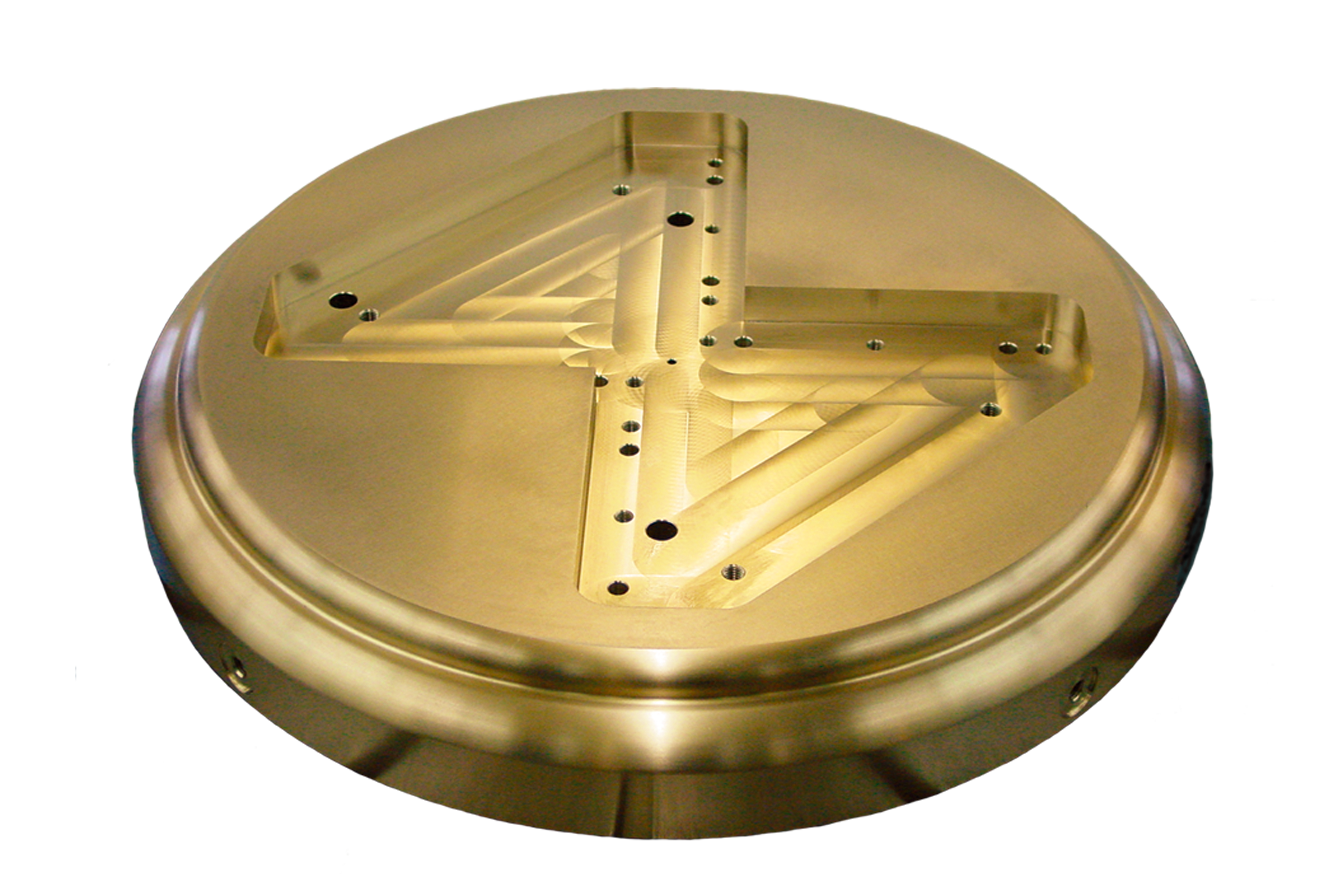

AMPCO® 25 curling tool for deep drawing

AMPCO® 25 curling tool for deep drawing Advantages for End Products and Industrial Applications

The surface quality achieved with AMPCO® alloys benefits both the manufacturing process and the performance of deep drawn steel components. For toolmakers and production engineers, the combination of low friction, high wear resistance, and excellent polishability results in stable forming conditions and consistent part output. For end users, it ensures components that meet strict visual and dimensional standards.

Key advantages include:

- Flawless part surfaces – minimized galling and pickup produce steel components with mirror-smooth finishes.

- Reduced secondary finishing – parts often require less polishing, cleaning, or coating preparation.

- Improved corrosion resistance – defect-free surfaces support uniform coating adhesion and long-term durability.

- Longer tool life – clean sliding contact reduces tool wear and extends service intervals.

- Reliable production consistency – stable tool performance supports predictable results in high-volume forming.

Across industries such as automotive, household appliances, and precision engineering, these characteristics translate into tangible cost savings and higher product value. AMPCO® 25 and AMPCO® 26 not only enhance surface quality but also ensure the repeatability and efficiency that modern manufacturing depends on.

Final Thoughts

Achieving flawless surface quality in deep drawn steel requires more than precise press control, it relies heavily on the performance of the tool material itself. AMPCO® aluminum bronzes, specifically AMPCO® 25 and AMPCO® 26, provide the hardness, polishability, and anti-galling behavior necessary to maintain clean tool surfaces and consistent part finishes over long production runs. Their combination of wear resistance and thermal stability ensures reliable forming conditions, even in high-pressure and high-output environments.

To explore more about advanced materials used in metal forming, visit the AMPCO Academy for in-depth articles, educational content, and expert insights.

For engineers and production specialists seeking technical specifications and real-world performance data, download the technical paper “Maximizing Performance in Deep Drawing with AMPCO® Aluminum Bronze.” It provides detailed comparisons, operational guidelines, and proven results demonstrating how AMPCO® 25 and AMPCO® 26 deliver superior surface quality and long-term reliability in deep drawing operations.