Additive manufacturing materials define the performance of every printed component, and thermal conductivity is one of the most critical properties. Copper alloys are emerging as the material of choice, offering the heat control needed for reliable, high-performance applications.

The effectiveness of additive manufacturing depends on more than process accuracy or design freedom. At the core of every successful build are the materials themselves, and their properties determine whether a part can meet industrial requirements. Among these properties, thermal conductivity plays a decisive role.

Copper alloys stand out because they combine high conductivity with the mechanical strength required for demanding applications. In additive manufacturing, this combination ensures efficient heat transfer, stability under load, and longer service life. As a result, copper-based solutions are redefining expectations for what additive manufacturing materials can achieve in both performance and reliability.

The Crucial Role of Thermal Conductivity in 3D Printing

In additive manufacturing, heat management is just as important as precision. Parts often face high temperatures and rapid heating or cooling, which can quickly affect performance. If heat is not controlled, components may lose efficiency, wear out faster, or even fail.

That is why thermal conductivity is such a critical property in additive manufacturing materials. It allows parts to handle demanding conditions and stay reliable over time. For example:

- Faster cooling in injection molds, which shortens cycle times.

- Consistent heating in inductors for greater process control.

- Longer service life by reducing thermal stress on parts.

- Stable operation in aerospace and energy systems that face extreme conditions.

Good thermal conductivity makes the difference between a part that only prints well and one that performs well in real-world use.

Copper Alloys as the Ideal Additive Manufacturing Materials for Heat Control

Not every material is suited for the demands of 3D printing. Many alloys can be printed, but they do not always deliver the heat management needed in real applications. This is where copper alloys stand apart.

Copper alloys combine high thermal conductivity and thermal conductance with the strength required for industrial use. In additive manufacturing, this means parts can transfer or dissipate heat quickly while still withstanding mechanical stress. Whether it is a mold insert, an inductor, or a heat exchanger, copper alloys provide a balance of properties that make them reliable in daily operation.

For engineers, this translates into fewer design compromises. Instead of choosing between conductivity or durability, copper alloys deliver both. Making them some of the most effective additive manufacturing materials for thermal control.

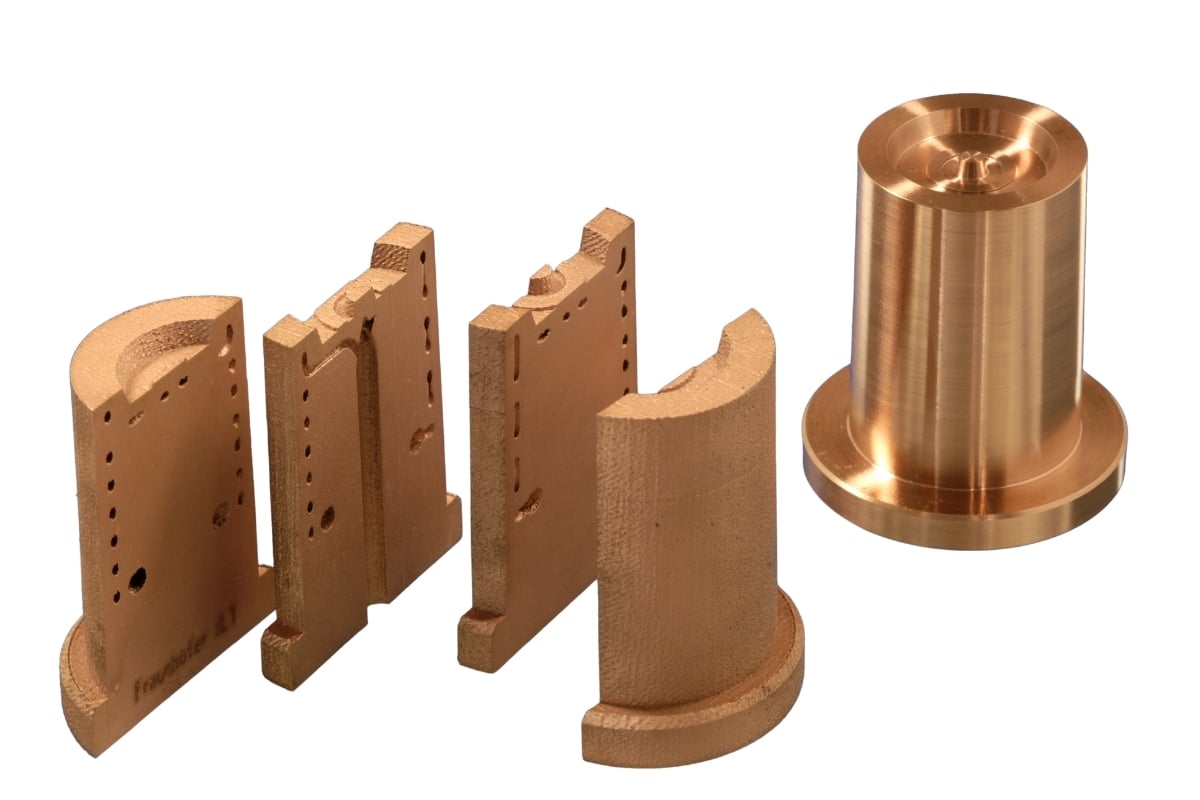

Copper additive manufacturing materials result in injection mold cores with very good properties

Copper additive manufacturing materials result in injection mold cores with very good properties

Use Cases from Mold Inserts and Inductors to Heat Exchangers and More

Copper alloys in additive manufacturing are proving their value in applications where thermal performance is critical.

Mold inserts

Conformal cooling channels can be printed directly into copper alloy inserts, something that is not possible with conventionally machined steel. The superior conductivity of copper alloys rapidly removes heat from molded parts, reducing cooling times and improving dimensional stability. This leads to shorter cycles, higher-quality surfaces, and fewer defects such as warpage.

Inductors

Induction systems require precise, localized heating with reliable thermal cycling. Additively manufactured copper alloy inductors provide excellent electrical conductivity while incorporating internal cooling channels that stabilize performance under continuous operation. Printing inductors as single, monolithic parts also eliminates soldered or brazed joints that could fail under repeated thermal stress.

Heat exchangers

Thermal devices rely on large internal surface areas to transfer heat efficiently. With copper alloys, additive manufacturing enables highly complex internal geometries, from lattice structures to ultra-fine fins, that would be impossible to machine conventionally. These designs maximize heat transfer while reducing weight and overall volume, making them especially valuable in space-limited systems.

Aerospace and energy systems

High-performance components in propulsion, turbines, or power electronics face simultaneous demands: extreme temperatures and heavy mechanical loads. Copper alloys balance high conductivity with strength, ensuring both effective heat management and structural integrity. This makes them uniquely suited for mission-critical components that must endure rapid thermal fluctuations and mechanical and dynamic loads.

These applications demonstrate that copper alloys are more than suitable for 3-d printing, thanks to their thermal performance and durability required in advanced industrial environments.

-Oct-27-2025-01-07-50-6246-PM.jpg?width=478&height=597&name=New%20Instagram%201080x1350%20(5)-Oct-27-2025-01-07-50-6246-PM.jpg) View of a particle distributor used in laser cladding devices

View of a particle distributor used in laser cladding devices

Final Thoughts

Thermal conductivity is a decisive factor in whether additive parts succeed in demanding industrial environments. Copper alloys stand out as additive manufacturing materials that not only print successfully but also perform under real operating conditions, from rapid cooling in molds to precise heating in inductors and efficient energy transfer in aerospace systems. By combining conductivity with mechanical strength, they provide a balance few other materials can match.

For professionals interested in exploring this topic further, the AMPCO Academy offers in-depth resources on additive manufacturing and material performance. Those looking for more detailed technical data and engineering insights can also download our technical paper "A Comprehensive Overview of Copper-Based Alloys for Additive Manufacturing" which explores the science and applications behind these solutions in greater depth.